An Overview of Our State-of-the-Art Manufacturing Facility

23500 CPH(Laser centering/Optimum)

From 0603 to 33.5mmsquare components

JUKI laser centering for high speed, high accuracy placement

Improved placement quality

Alternate pick by screw-type nozzles* achieves high-speed placement for large component up to 25 mm diameter

High-precision placement of diffusion lenses

Capable of up to 1,500 mm long board production

Top class board size in industry.

Visual Inspection

Burn-in test for Reliability

Functional Testing

Component Procurement & Sourcing:

We collaborate with a diverse network of trusted suppliers to procure components for your prototype. Whether you’re in need of standard parts or specialized items, we make sure that only the highest-quality materials are incorporated into your design.

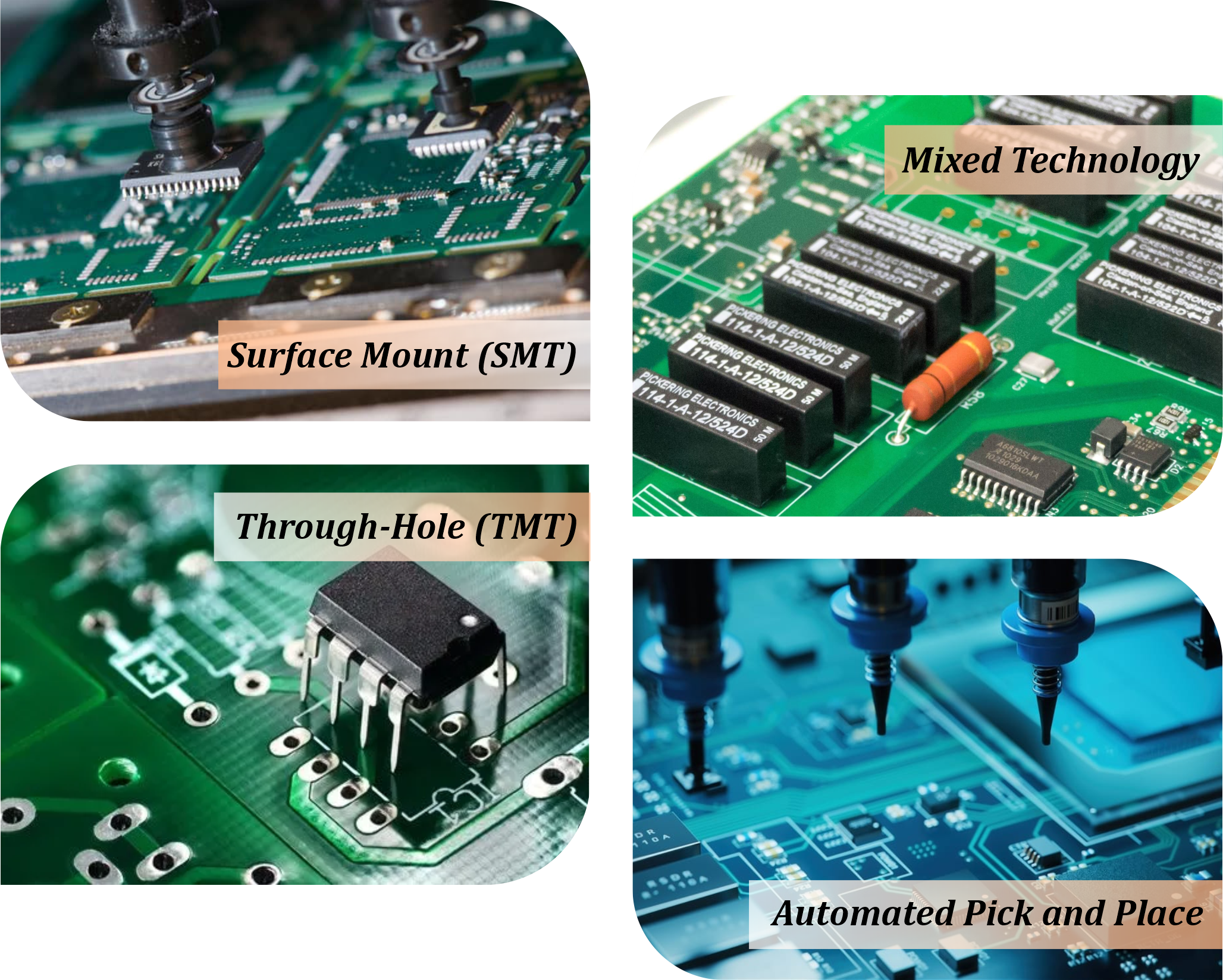

Our talented technicians use cutting-edge assembly techniques, including:

Surface Mount Technology (SMT) for those tiny components

Through-Hole Technology (THT) for the bigger parts

Mixed Technology Assembly for designs that need both SMT and THT components

Automated Pick and Place Machines for accurate component placement

We provide top-notch soldering methods, including lead-free options, to guarantee strong and durable connections on your PCB. If any hiccups come up during assembly, we offer rework services to fix issues like misalignments or soldering flaws.

Our prototype assembly process is all about being quick and adaptable. We know that a fast turnaround is essential during the prototype stage, so our facilities are set up to manage rapid assembly with short lead times, all while maintaining high quality.